Understanding Final Drive Motors: The Heart of Efficiency in Machinery

Final drive motors play a crucial role in the smooth operation of a wide variety of machinery, from heavy construction equipment to motorcycles. This article delves deep into what final drive motors are, how they function, their applications, and tips for selecting the right one for your needs. By the end, you’ll have a comprehensive understanding of these essential components and how they contribute to efficiency in various automotive and industrial contexts.

What is a Final Drive Motor?

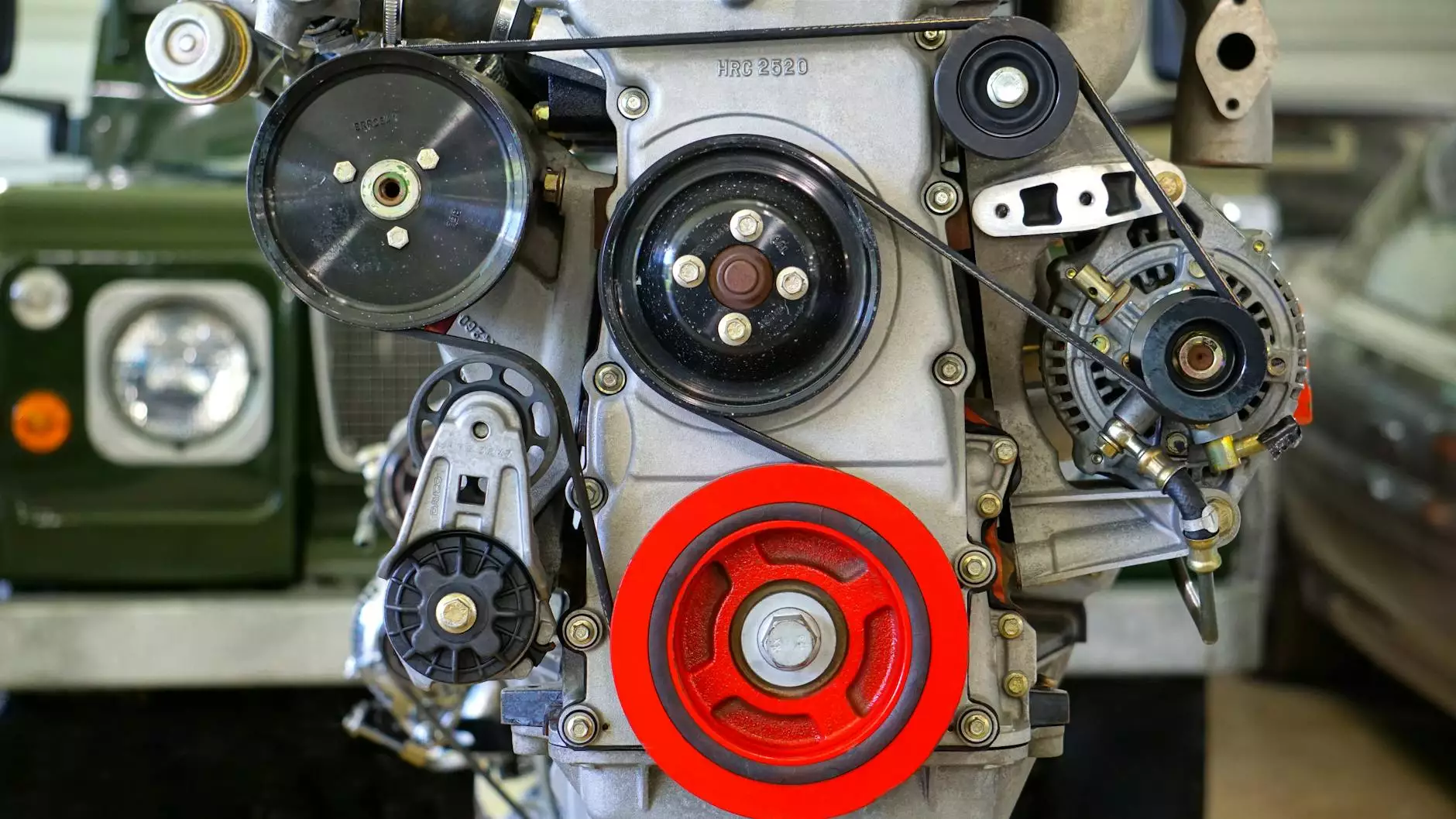

At its core, a final drive motor is a specialized type of motor designed to transfer power from a hydraulic motor to the final drive assembly of vehicles and heavy machinery. It plays a vital role in converting rotational motion into linear force, which drives the wheels of an automobile or the tracks of heavy equipment. Understanding the anatomy of a final drive motor is important for anyone involved in machinery operations, repairs, or enhancements.

The Anatomy of Final Drive Motors

Final drive motors consist of several key components that work in unison. These include:

- Gearbox: The gearbox is responsible for reducing the speed of the motor while increasing torque, allowing for better handling of heavier loads.

- Sprocket or Gear: This connects to the drive mechanism, transmitting power from the motor to the wheels or tracks.

- Housing: The outer casing that protects internal components from external elements.

- Seals and Gaskets: These prevent leakage of oils and contaminants, ensuring longevity and reliability.

How Do Final Drive Motors Work?

The operation of a final drive motor can be seen as a two-part process:

- Power Generation: The motor receives hydraulic fluid, which powers the motor through pressure differentials.

- Power Transmission: After generating power, the motor transmits it to the final drive gear assembly, enabling the machinery to move.

This efficiency in power transfer is what makes final drive motors indispensable across various applications, ensuring smooth operational flow and optimal performance.

Types of Final Drive Motors

Final drive motors come in various types, each suited for specific applications. Here are the most common types:

- Hydraulic Final Drive Motors: These motors use hydraulic pressure to operate, making them ideal for heavy machinery like excavators and bulldozers.

- Electric Final Drive Motors: Increasingly popular in modern vehicles and machinery, these motors are pollutant-free and efficient, perfect for applications where noise reduction and energy efficiency are priorities.

- Pneumatic Final Drive Motors: Utilized in specific industrial settings where air pressure can drive motion, these motors are excellent for light-duty operations.

Applications of Final Drive Motors

Final drive motors are ubiquitous in many industries. Here are some key areas where they are essential:

- Construction Equipment: Final drive motors are foundational in machinery such as excavators, loaders, and bulldozers, delivering the necessary torque and power for heavy lifts.

- Automobile Manufacturing: In vehicles, they contribute to the overall drivability by facilitating power transfer in various types of drive systems.

- Agricultural Machinery: Tractors and harvesters rely on final drive motors to maneuver through fields efficiently, providing the necessary power for challenging tasks.

- Motorcycles: In two-wheeled applications, final drive motors enable smooth acceleration and power management, contributing to an enjoyable riding experience.

Benefits of Using High-Quality Final Drive Motors

Choosing high-quality final drive motors offers numerous advantages:

- Enhanced Performance: High-quality motors ensure optimal power transfer, improving overall vehicle performance.

- Longevity: Quality manufacturing means better durability and resistance to wear and tear, reducing replacement costs.

- Efficiency: Well-designed motors operate at higher efficiencies, meaning less energy is wasted and more power is delivered to the drive system.

- Reliability: Dependable components mean less downtime and maintenance, keeping your operations running smoothly.

How to Choose the Right Final Drive Motor

Choosing the right final drive motor can be challenging given the variety of options available. Here are some factors to consider:

- Application Requirements: Understand the specific needs of your machinery or vehicle to select a motor that fits those requirements.

- Torque and Power Ratings: Check the torque and power ratings to ensure the motor can handle the intended load and performance demands.

- Compatibility: Ensure that the motor is compatible with your existing systems to avoid costly modifications.

- Warranty and Support: A good warranty and customer support can be invaluable in case of defects or performance issues.

Tips for Maintaining Final Drive Motors

Proper maintenance extends the lifespan of your final drive motor and enhances reliability:

- Regular Inspections: Inspect the motor regularly for any signs of wear, leaks, or damage.

- Fluid Maintenance: Keep the hydraulic fluids clean and at the recommended levels, changing them as per manufacturer guidelines.

- Cleanliness: Maintain a clean environment around the motor to prevent dirt and debris ingress that can cause damage.

- Professional Servicing: Schedule professional maintenance to ensure that your equipment stays in peak condition.

The Future of Final Drive Motors

The future looks promising for final drive motors, with advancements in technology driving innovation:

- Integration with Smart Technologies: With IoT becoming more prevalent, final drive motors are expected to be integrated with smart monitoring systems providing real-time data.

- Increased Energy Efficiency: Ongoing research into materials and design will likely result in even more efficient versions of these motors.

- Sustainability: There is a significant shift towards electric and hybrid technologies in vehicles that will revolutionize how final drive motors are engineered.

Conclusion

In summary, final drive motors are invaluable components in a wide array of vehicles and machinery, ensuring efficient power transfer and optimal performance. Whether in construction, automotive, or agricultural applications, understanding their importance can significantly impact operational efficiency. For businesses in the automotive and machinery industries, investing in high-quality final drive motors not only enhances performance but also promotes sustainability and operational excellence.

As you consider your options for final drive motors, remember to leverage the wealth of knowledge available through reputable sources and experienced merchants like Shop Hydraulic America. With the right information and tools, you can ensure that your machinery and vehicles operate reliably and efficiently for years to come.